Batching

The concrete was produced using the

concrete mixing station at the DTI laboratories. The main challenge

of the concrete production was to comply with the requirement of

less than 1% batching deviation on the individual constituent. In

particular the water content was a challenge and a special

procedure for controlling aggregate moisture content was

established.

In connection with the production

of each batch of concrete the moisture content in the individual

aggregate fraction was determined by micro wave drying on three

samples of approximate 1 kg each taken directly from the material

actually batched, i.e. from the material on the conveyor belt. The

adopted procedure also allowed to batch exactly the nominal amount

of aggregate as material could be added or removed from the

conveyor belt to equal precisely the desired amount. The total time

required to obtain the moisture content of four aggregate fractions

was approximately 25 minutes. During this time the aggregate was

resting in the closed confines of the mixer, i.e. no moisture loss

took place. From the measured moisture contents the exact amount of

water needed to obtain the w/c-ratio was calculated and

subsequently batched.

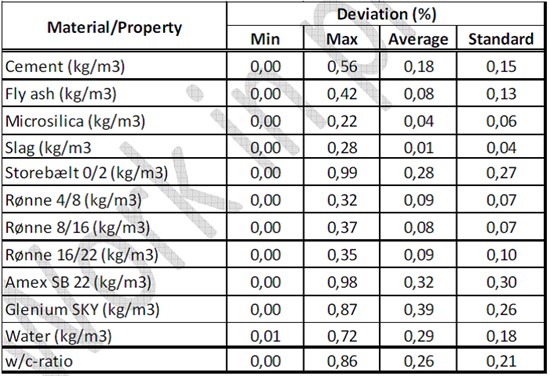

The maximum deviation on the

w/c-ratio was 0.86 % corresponding to values between 0.397 - 0.403

for a nominal value of 0.400, i.e. roughly 10 times better than

what is typically achieved by industrial concrete mixing

stations.

Based on the data for the +60

batches of concrete produced, the minimum, maximum, average and

standard deviations obtained for the individual

constituent.

The mixing station is equipped

with a 375/250 liter counter-current mixer, five aggregate silos

and four powder silos from Haarup A/S, and process control software

from Skako A/S. Prior to initiation of the project all weight cells

were calibrated using traceable weights. All materials were batched

based on weight.